Textile Innovation with Ghost White Toner: Double Pass printing

In a world where visual communication dominates, print quality plays a crucial role. Ghost White Toner has initiated a revolution in the printing industry with its ability to bring radiant white to dark and colored substrates. The Double Pass is a technique that further advances this innovation. In this article, we explore the significance of the Double Pass and how it opens new dimensions in textile inovation printing when combined with Ghost White Toner.

What is a Double Pass and why is it used?

The Double Pass is a special printing method perfectly suited for the use of Ghost White Toner in laser printers. The reason for this method lies in the technical limitation that a printer is not usually capable of printing CMYK and white simultaneously in one pass. Therefore, people employ the Double Pass to print designs containing both colors (CMYK) and white in two separate passes.

The Double Pass is utilized in the production of transfers, especially for textiles. First, they print the colorful CMYK colors onto the transfer paper. Then, they add white in the second pass. This is crucial for transfers because light and pastel tones on dark or colored fabrics would lack sufficient contrast and adhesion without a white base. The special adhesive from the B-paper used for textile transfer requires an adequate amount of toner to firmly bond with the fabric. Without the white layer as a foundation, the adhesive would not have enough color to anchor itself, resulting in an unsuccessful transfer. The Double Pass ensures that a solid white layer lies beneath the colorful inks, improving the adhesion of the adhesive and thus ensuring the quality and longevity of the transferred design onto the textile.

How does a Double Pass with Ghost White Toner work?

The Double Pass with Ghost White Toner is a multi-step process that requires careful preparation and execution, especially when it comes to transfers on textiles. The process includes the following steps:

- Print Preparation: For a successful Double Pass, compatible laser printers and meticulous preparation of the print file are necessary. First, begin by correctly setting up the print file. This involves creating two separate files: one file in CMYK color mode for the colorful inks and one file with a black mask, which will later be used for the white underprint. Since it’s a transfer, both files must be mirrored.

- First Printing Pass: In the initial step, print the CMYK file onto the A-sheet. This establishes the colored base for the design.

- Toner Change: After the first printing pass, replace the black toner in the printer with the Ghost White Toner.

- Second Printing Pass: Print the A-sheet again, this time with the file for the white underprint.

Following these steps, further processes for the transfer occur, such as compressing the A-sheet with the B-paper, transferring the design onto the textile, and finally fixing it to ensure the quality and durability of the transfer.

Important Aspects and Limitations of the Double Pass

Precision in the Double Pass is crucial to achieve a clean and professional printing result. If the two printing passes – the CMYK print and the white underprint – do not align exactly, shifts can occur.

Since each printer has individual offsets, it is sometimes not possible to completely avoid this offset. Therefore, the print file must be adjusted accordingly. For instance, adjusting the file for the white underprint can compensate for any offset. Typically, reducing the black mask area by about 3 pixels is a common approach. This ensures the white underprint is slightly smaller than the colored print, preventing the white layer from extending beyond the colored edges and maintaining a clean and precise result.

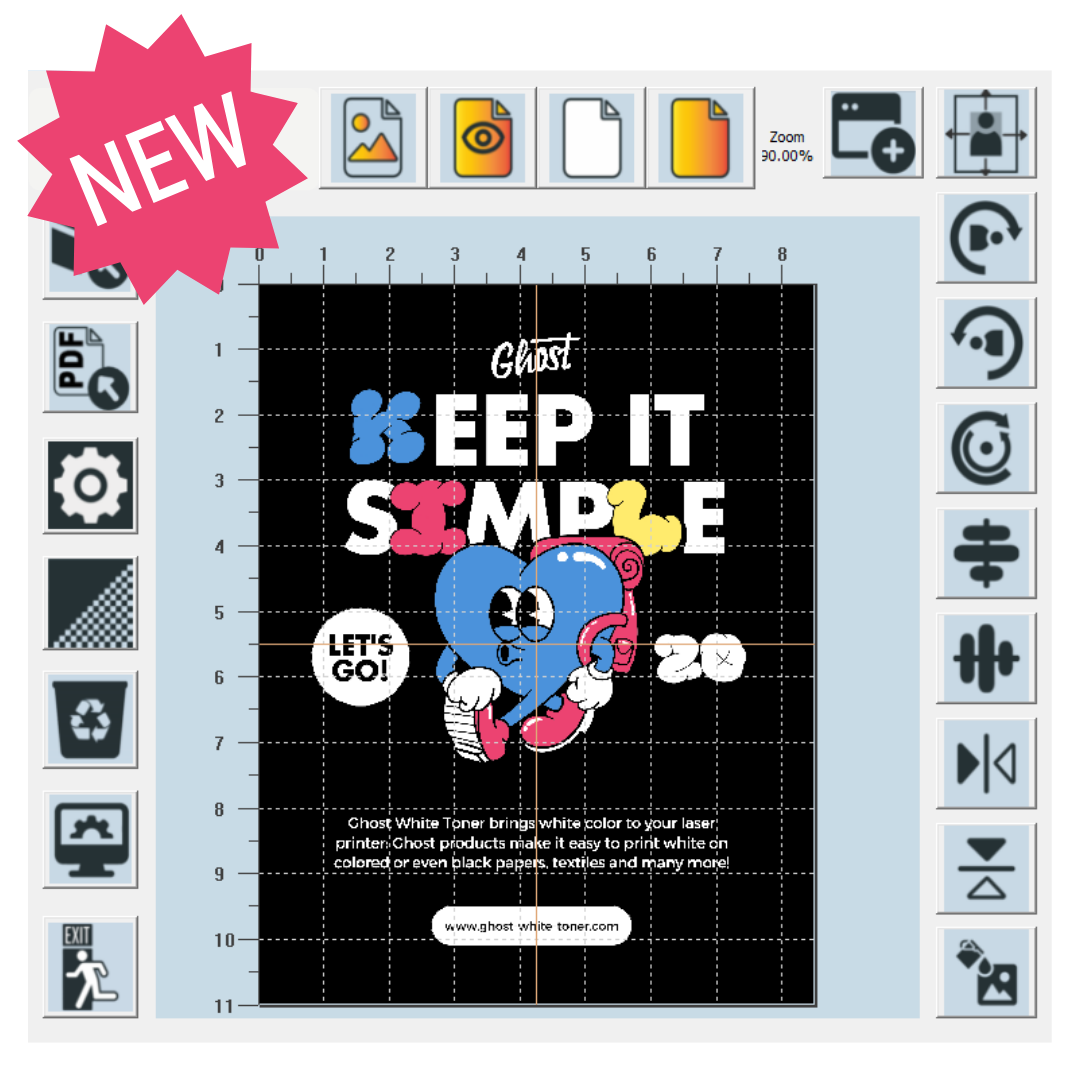

Properly preparing the file requires accurately defining the white areas of the design. Here, the Absolute White RIP – Ghost Edition provides valuable support. This tool assists in preparing the files to execute the Double Pass more precisely and effectively.

When is a Double Pass not possible?

Obstacles also arise when the printer is not precise enough to print the paper exactly twice on top of each other, or when the design is too small to allow for proper registration. Irregular or very thick paper that cannot reliably pass through the printer also presents a hurdle for a successful Double Pass. In such cases, the quality of the printing result may be compromised or the printing process may even fail. Therefore, it is important to ensure that both the printer and the printing material are suitable for a Double Pass to achieve optimal results.

Conclusion

The Double Pass with Ghost White Toner is an advanced technique that can significantly improve print quality. Proper application and consideration of technical requirements are essential for successful printing results. With these prerequisites, the Double Pass enables impressive print products for a variety of applications.

Discover the possibilities offered by Ghost White Toner and experience the difference that a Double Pass can make in your printing projects.

Find your Ghost White Toner

And start printing White!