The flock print for long-lasting results

Flock printing is a process that is quite similar to flex printing. It is ideal for finishing textiles like sweaters, shirts or fabric bags. The logo, lettering or a suitable motif is cut out and welded onto the textile, which leads to a particularly long-lasting result.

The pleasantly soft feel and the thickness of the applied objects stand out from the results. They are about half a millimetre higher and thus differ greatly from other results such as those achieved with sublimation printing. In addition, they are matt, non-gloss surfaces in a maximum of three colours, which distinguishes flock printing from other methods. We will explain how this work is done and what flock printing is best suited for.

How flock printing works

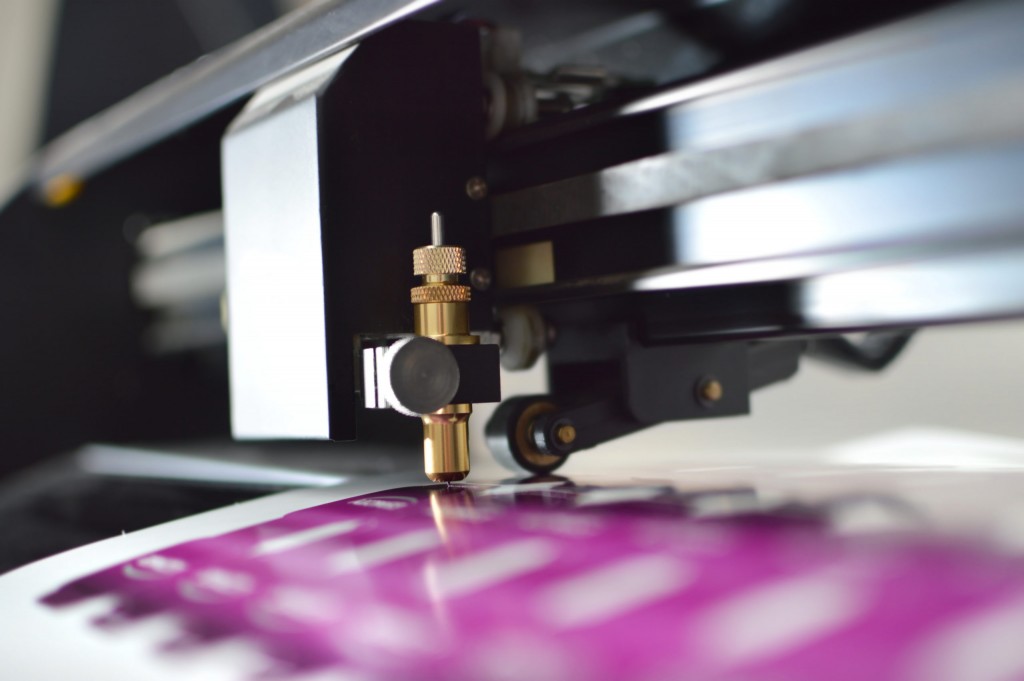

Flock printing works in many ways like flex printing, and special films are also required for this. First of all, vector graphics are created with a corresponding computer program, which are often single-coloured, but may be a maximum of three colours. The motifs are cut or scored out of the foil with a vinyl cutter. The carrier film must now be weeded. During this process, any excess film is manually removed so that the desired symbol, logo or typeface appears.

Now the exempted motif is placed on the textile at the desired position and covered with a protective paper. It can now be applied to the material in the transfer press using heat and pressure. The result is resistant and shines brightly. With this modern method even small quantities can be produced easily and inexpensively.

Modern flock printing (and flex printing):

- create vector graphics with maximum 3 colours

- check settings and insert foil

- use a vinyl cutter for plotting (cutting/scoring)

- weeding manually

- transfer the exempted motif onto the textile with a press

However, flock printing can also be done in a completely different way and was for a long time realised on a larger scale than a variant of screen printing. In the much more complex process, a disposition adhesive is applied to the areas to be decorated. Flock fibres are then applied to this. The exact process is roughly as follows:

The basis for the process is a metal plate with connected electrostats. The textile to be decorated is placed on this plate with the special adhesive. Exactly above it there is a container with a sieve on is attached to the bottom side, which is also connected to an electrostat. At the bottom of the vessel filled with the flock fibres there is a sieve which later releases them.

In the next step a high voltage generator generates a voltage and the flock fibres shoot through the sieve. They do this because an electrostatic field is created between the plate and the screen. At all places where glue is applied – i.e. where the motif will later be located – the particles remain stuck, while the remaining flock fibres can be reused. In the last step the fibres have to dry on the glue. For this they are stored in a drying oven. The result has a particularly good feel, reminiscent of plush.

Properties of flock printing – what is flock printing suitable for?

Depending on the textile, different motifs and sizes are possible. Small logos, emblems, filigree lettering and the like are ideal for T-shirts. The colours and the fastness to feel are preserved even after many washes. The special thickness makes the motifs look noble. However, very fine lines and symbols should not be placed on seams, as these could become cracked.

Rather large motifs are suitable for thicker fabrics such as sweatshirts or robust jerseys. A very popular application of flock printing are large back numbers on jerseys, which are clearly visible and of high quality. The contrast between number and jersey is shown to its best advantage by flock printing.

Features at a glance:

- Remarkable haptic, soft & grippy

- Long shelf life

- Easy to clean

- Colourfast

- Good contrast possibilities for large areas

- Noble results with small logos & Co.

In general the application on cotton and fabrics with a high cotton content is recommended. The material adapts itself optically and in terms of grip especially well. However, the application possibilities of flock printing are variable and especially the smart version with cutting plotter makes this process very attractive for users who work with high-quality materials. The results, especially from industrial flock applications, are convincing and can be ideally combined with toner transfer. Screen printers can thus expand their portfolio by offering individualization of single runs with toner transfer.

Photo credits:

ghazii – stock.adobe.com

alphacero – stock.adobe.com