The plotter print at a glance

Plotter printing is a relatively general term that refers to various printing techniques in connection with the name-giving plotting. Plotting (from English to plot – “to draw”) means in practice as much as cutting and scribing. Different materials are suitable for plotting or require this type of processing. In addition to plotting on a large, industrial scale, this technique is also used for designing textiles.

The materials to be plotted are mainly transfer films such as flex films, flock films or vinyl films. These are on a carrier film and in most cases must be weeded after plotting. In the following we will go into more detail about plotter printing for materials used to design textiles. Apart from that there is another type of plotter printing. In the industrial printing industry, sheets of paper or rolls of various types of paper are plotted, including photo paper or films.

How does plotter printing work in the textile industry or for private use?

Depending on which transfer material is chosen, the patterns, logos or images must be created as simple graphics or vector graphics. With vinyl printing, the final transfer after plotting and weeding is done differently than with flock and flex printing, which is why the motifs are realised as they appear on the textile. With flex and flock printing, the motifs are created mirror-inverted. This is of elementary importance especially for lettering, as these would not be readable without mirroring during transfer.

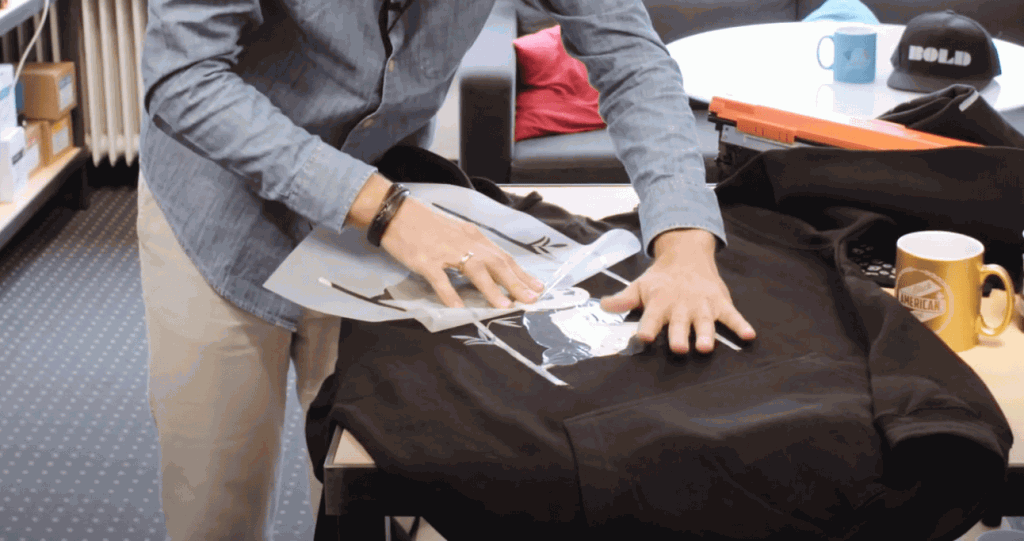

With the help of a cutting plotter, the films are produced which, after weeding, are transferred to the textile via a transfer press under pressure and heat. When making motifs, various circumstances must be considered. You can very well provide work clothes and sports equipment with your desired logos or lettering and back numbers. Especially jerseys are very often refined in this way. Plotter printing usually uses only one or two colours, which limits the possibilities. However, you are free to choose the finish and you can make the objects matt, shiny or even glittering.

Weeding is a manual step that requires time and experience. Here we recommend a simple and smart alternative. With special Flex-Soft-Foils (no cut) from Ghost you can realize your creative ideas in several colors and you don’t have to cut or weed them, because these foils are self-weeding. For the classic procedure you need tools like (cutter-)knives and special weeding hooks. Read more about the cutting and weeding process in our article on vinyl printing or flex printing.

After this step you transfer the respective foils to another transfer foil mirroring them. Then you place them – self-adhesive in the case of vinyl films – on the textile and press them together. Under pressure and heat this process takes only a few minutes with a modern transfer press. If you work a lot with such methods, you only have to use a plotter and the press has higher acquisition costs, but can then flexibly design and produce smaller series individually. Plotter printing in its facets is a frequent design option when finishing clothes and bags.

The motifs can be produced very small or in DIN A4 or A3 formats. Due to the material properties, however, the films are not breathable and are more likely to be damaged if they are large. Therefore, they are in demand as emblems, logos, for lettering and numbers, while large-area images are applied to clothing using other techniques. See toner transfer with black toner, color toner or our Ghost White toners.

Plotter printing in the industry

Far away from the small formats used for plotter printing with textiles, large machines are used for conventional plotter printing in the printing industry. These plotters print and plot paper sheets in all conceivable sizes from A3 to A0 as well as in special sizes. Very often it happens that the paper is guided on huge rolls and therefore printing and plotting can be done on a continuous basis, one paper meter at a time.

These plotter printers are also equipped with ink jet buttons or so-called ink pens and process very different types of paper, photo paper and foils. The product range in this area is versatile and ranges from billboards, posters & Co. to large-format posters for indoor or outdoor use, photo walls and many other things. In professional print shops the products are refined after plotter printing and protected with dispersion varnish, for example.

As can be seen here, this type of plotter printing is not for small companies or even for private use. Due to the high machine costs and their size alone, small or medium-scale requirements must be outsourced to special printing services and printing companies.

The premium plotters of this type are produced as roll plotters or flatbed plotters and can cost tens of thousands of Euros.