Vinyl cut print

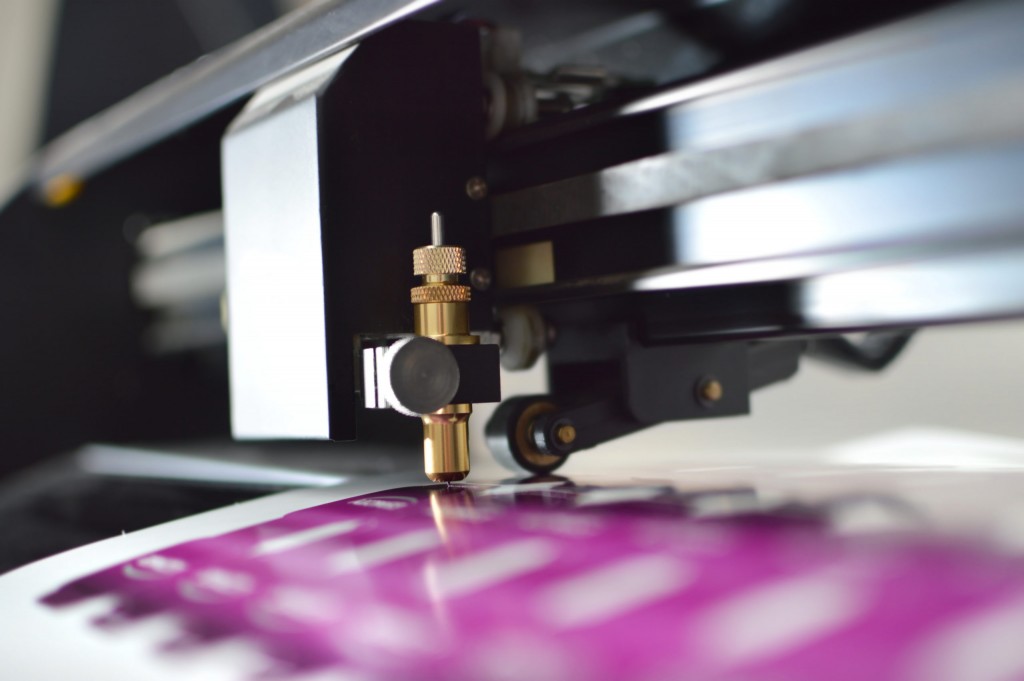

Vinyl cut printing, also called vinyl foil transfer printing, is a process in which the motifs to be transferred are cut out of special plastic foils. These so-called vinyl foils are mostly smooth, occasionally also matt soft. Various textiles such as cotton fabric, viscose, nylon, several polyesters and numerous blended fabrics made of these materials serve as carrier materials. When designing the motif, up to three colours are selected to form it as an image, logo or lettering. Vector graphics, i.e. schemes without colour gradients, are implemented in the printing process. To carry out this process, vinyl foils, a cutting plotter and a transfer press are required for the final transfer to the textile.

The procedure for vinyl cut printing

In the beginning there is the design of a desired motive as vector graphic. Various programs such as Adobe Illustrator and others are suitable for this. The image itself can consist of up to three colours, which are strictly separated from each other. Colour gradients are not possible. For an optimal picture, sizes of about 30 cm x 30 cm are recommended. Large-area motifs are not recommended for various reasons, for example because of the films’ lack of breathability and susceptibility to creasing.

The individual areas of the designs should be at least 1 mm apart and the line thickness of the details should be at least 1.5 mm. If the design has been laid out correctly, it can be cut out using a cutting plotter, also known as a vinyl cutter. However, cutting out means rather a scratching, so that the motifs can be easily removed. Unfortunately, this work step is very laborious and has to be done by hand. It is also called weeding or cropping.

The process in a few steps:

1. create the motif as a vector graphic and cut/score the vinyl foil with a vinyl cutter (plotting).

2. remove/weeding the excess material manually.

3. apply the logo, pictogram or lettering to the carrier material/fabric

4. transfer the vinyl foil motif onto the fabric using a transfer press.

The motifs exposed in this way are placed on the material in the final work step and cleanly applied by a transfer press. The result is characterised by high quality in terms of edge sharpness and wash resistance. In addition, the colour brilliance is particularly high and strong contrasts are shown to their best advantage. The feel is pleasant and the garment is permanently enhanced.

What is vinyl printing suitable for?

Due to weeding, vinyl printing is not suitable for long runs. As a process, it is suitable for smaller runs and single pieces that can be produced quickly. In addition, the purchase costs for the required equipment are manageable and vinyl foils are very inexpensive. With more special films, such as those offered by Ghost, self-weeding films can also be purchased. These can not only be multicoloured, but also have special effects and glitter or support a metallic look.

Due to the way they are made, symbols, lettering, logos and pictograms are particularly suitable for implementation. With these motifs the limitation to single colours is also less tragic. The bright motifs become real eye-catchers and are ideal for advertising companies and brands in other contexts. Filigree and detailed motifs are only possible to a limited extent, as the process of weeding is time-consuming and prone to errors. Since the films are not breathable and simply have a different consistency than the rest of the fabric, larger areas on sweaters or T-shirts are not recommended. Quality, durability and wearing comfort would suffer.

Vinyl printing is therefore particularly suitable for monochrome and not detailed motifs. However, very good results can be achieved there at low cost. As an alternative to vinyl printing, toner transfer with Ghost White toners offers far more possibilities. Due to modern colour laser printing, multi-coloured motifs and photos are no problem. The self-webbing transfer films Laser Dark and Flex Soft allow the transfer of filigree and detailed motifs without weeding or cutting out. The durability, colour brilliance and washability of textiles is similar in both processes. The slightly higher investment in a laser printer with Ghost White Toner is compensated by a time-saving work process and considerably more possibilities.

The care of textiles with vinyl print motifs

Vinyl prints are resistant and can withstand numerous washing processes. The danger of creasing exists especially with too large motifs. Otherwise, washes up to 40 degrees are no problem. The vinyl foils are heat-resistant to a certain degree. However, in order to maintain their durability, garments with vinyl print motifs should be ironed from the left.

Not only the film itself but also the substrate is partly responsible for the durability of the results. High-quality garments should therefore be selected as the basis for the motifs. With premium T-shirts and other high-quality pieces you will get a consistently beautiful result that is easy to maintain.